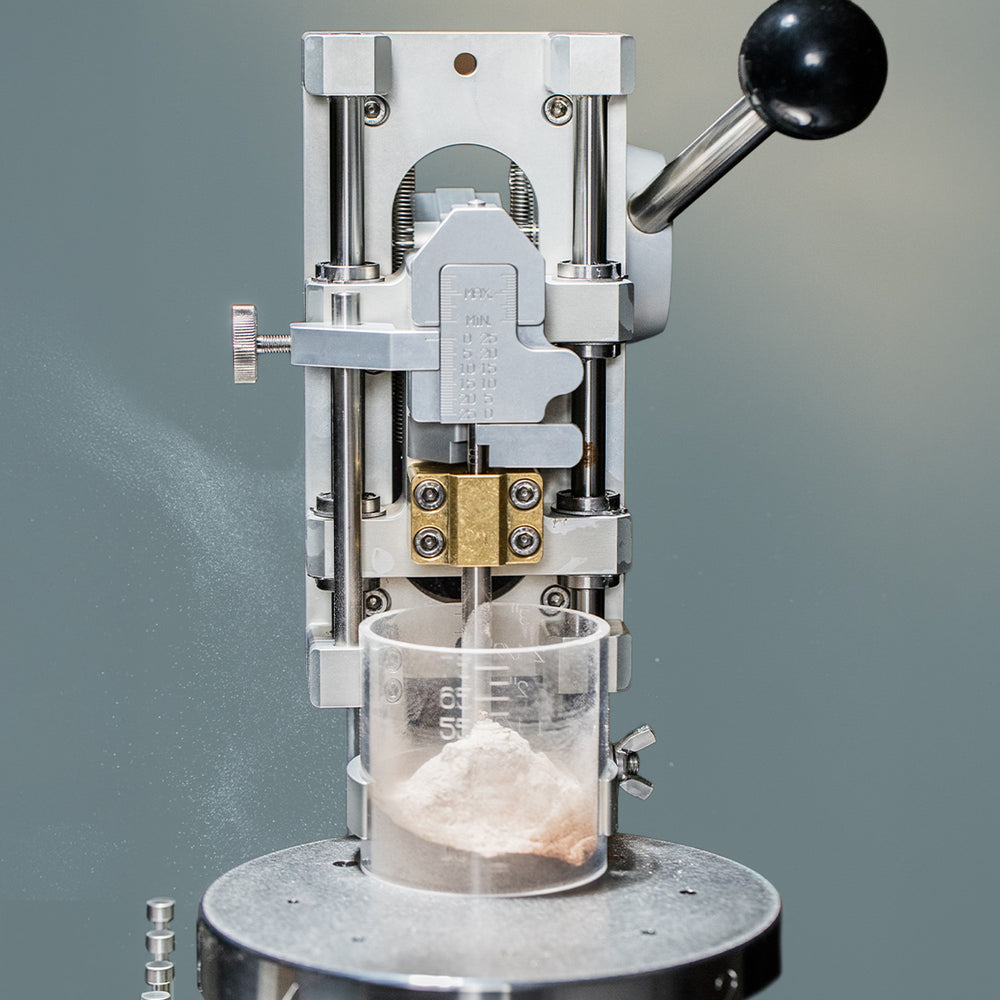

The Tamping Simulator is used to develop and improve slug formation during capsule filling. It allows manufacturers to test dosing and compression parameters before full-scale production, helping ensure consistent weights and reliable capsule joining.

Yes. The device works with your actual formulation, allowing you to evaluate how different powders behave under real tamping and compression conditions before moving into production.

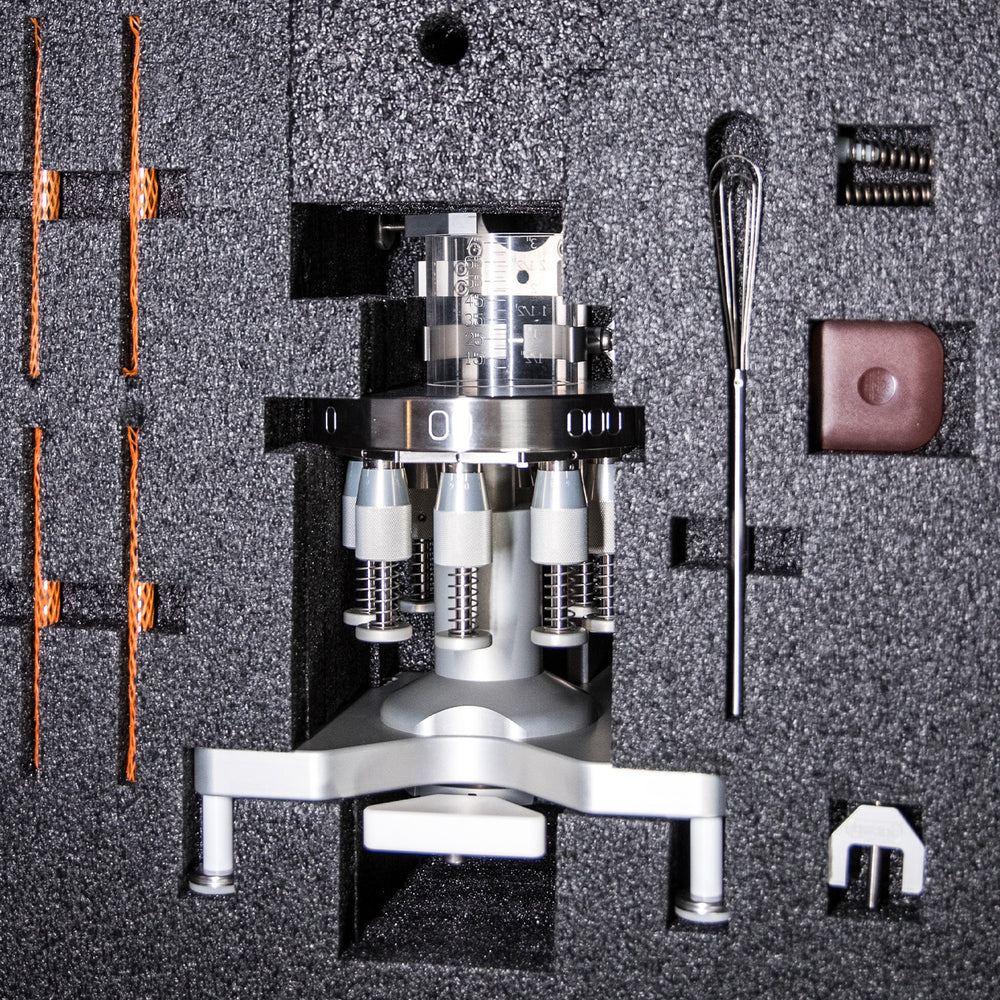

Absolutely. The Tamping Simulator is designed for both R&D and full manufacturing environments, supporting formulation development, process optimization, and confident scale-up to production.

By allowing operators to predefine dosing and compression settings, the tamping tool reduces trial-and-error during machine setup, minimizing material waste and shortening set-up times.

Yes. Replicating real tamping conditions helps identify optimal parameters for consistent slug formation, leading to improved weight uniformity and fewer capsule joining defects during production.

The tamping simulator is made of stainless steel, recognized in the pharmaceutical and food industry for its exceptional corrosion resistance, non-reactive nature, and ability to withstand rigorous sanitation, ensuring product purity, safety, and regulatory compliance.